![]() Hot Water Storage Tanks

Hot Water Storage Tanks

![]() Asphalt Storage Tank Heaters

Asphalt Storage Tank Heaters

![]() Heating & Preheating All Grades of Oil

Heating & Preheating All Grades of Oil

![]() Food Processing Equipment

Food Processing Equipment

![]() Cleaning and Rinsing Tanks

Cleaning and Rinsing Tanks

![]() Process Air Equipment

Process Air Equipment

![]() Boiler Equipment

Boiler Equipment

![]() Freeze Protection of Fluids

Freeze Protection of Fluids

![]() Petro-Chemical

Petro-Chemical

Description

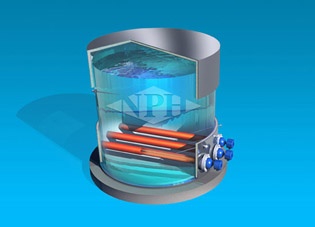

Pipe Insert immersion heaters are ideal for applications where direct contact of the liquid and the heating element are to be avoided; or in large storage tanks where draining the tank, in the event a heater needs replacing, is difficult. Pipe insert immersion heaters give you the optimum choice for these situations. These heaters require the installation of separate pipes inside a tank.

While maintaining 100% energy efficiency, the radiation and conduction from the element to the inner pipe wall gently transfers the heat to your liquid. This is an ideal method for heating viscous or corrosive products.

Pipe insert immersion heaters are designed to fit into a schedule 80 pipe and are available for screw plug or flanged mountings. The most common sizes are the 2 in NPT steel screw plugs and the 3 in 150 lb flanges. Other sizes and alloys are available to suit your needs.

All pipe insert immersion heaters have (NEMA 4) weather proof terminal boxes.

When more than one heater is needed, mount the pipes in parallel rows to avoid liquid overheating in the centre from a wagon wheel installation. Low liquid protection is available by including an optional type K thermocouple built into one of the heaters. It is suggested this unit be mounted about 6″ above the other heaters to give you the best response time.

Pipe Insert Heaters: Specifications, Manuals, Technical Letters & Tips:

Flanged Immersion Heaters Specifications.pdf

Flanged Immersion Heaters Specifications.pdf

How to Extend the Life of Your Immersion Heater-2.pdf

How to Extend the Life of Your Immersion Heater-2.pdf

Pipe Insert Immersion Heaters Wiring Diagrams.pdf

Pipe Insert Immersion Heaters Wiring Diagrams.pdf

Pipe Insert Heaters-Installation, Operation and Maintenance NL.pdf

Pipe Insert Heaters-Installation, Operation and Maintenance NL.pdf